Download

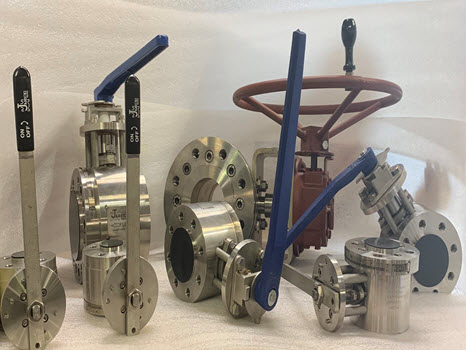

Aerospace Valves

Jarecki Valves has built numerous aerospace valves in a variety of materials and pressure classes. We provide high-temperature V Port Control Valves to handle hot exhaust, targeting areas such as stem leakage, seat leakage, performance, and endurance—Jarecki developed a line of valves which have proven to meet every one of these goals. Our quality control program requires that every valve has a seat leakage test, a hydrostatic test, and a torque test performed, before it leaves the factory.

SHUT-OFF/MODULATING BALL VALVES LOW PRESSURE

SV Series Ball Valves are floating ball valves with a two-piece ball and stem. They are flanged valves in pressure classes 150# and 300#. They are an excellent choice for low cost metal seated ball valves. With the Phantom Port Modification they are the best low pressure valve on the market. The SV series can be used for shut-off but it can also be used for control with the V Port option. These valves are available in a number of special alloys.

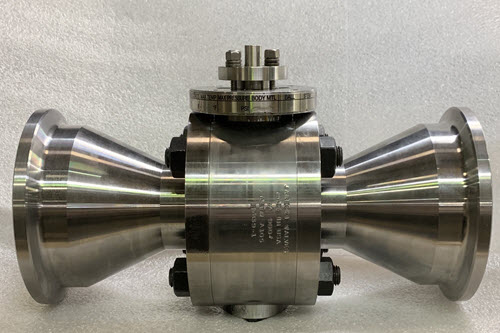

SHUT-OFF/MODULATING BALL VALVES HIGH PRESSURE

Our 2000 Series Ball Valves are available in any alloy. These American-made aerospace valves feature a sturdy design produced from either bar or forgings. It is available in pressure classes from 150# to 2500#. Soft seats and metal seats are both available in this valve series. Because of the heavy wall the metal seats are very robust and have multiple seals for very reliable sealing over a long period of time.

SHORT PATTERN VALVES

5000 Series Ball Valves are available in any alloy. This American made product features a very solid design produced from either bar or forgings. It is a short pattern valve so there is a savings when dealing with high alloy material. The 5000 series is an excellent choice if space and weight are a consideration. It is available in pressure classes from 150# to 2500#. Soft seats and metal seats are both available in this valve series.