New Design For Aerospace Testing

When an Aerospace testing facility required a control valve to handle a sudden increase in temperature from 200 deg F to 1500 deg F Jarecki responded. A 2500# Inconel 625 ball valve was designed with Inconel 718 trim. Thermal expansion was a big problem and previous valves had locked up under these conditions. Utilizing locating springs on the valve trim allowed for rapid expansion without affecting performance of the valve. Heat dissipating baffles on the coupler protected the actuator from the extreme heat.

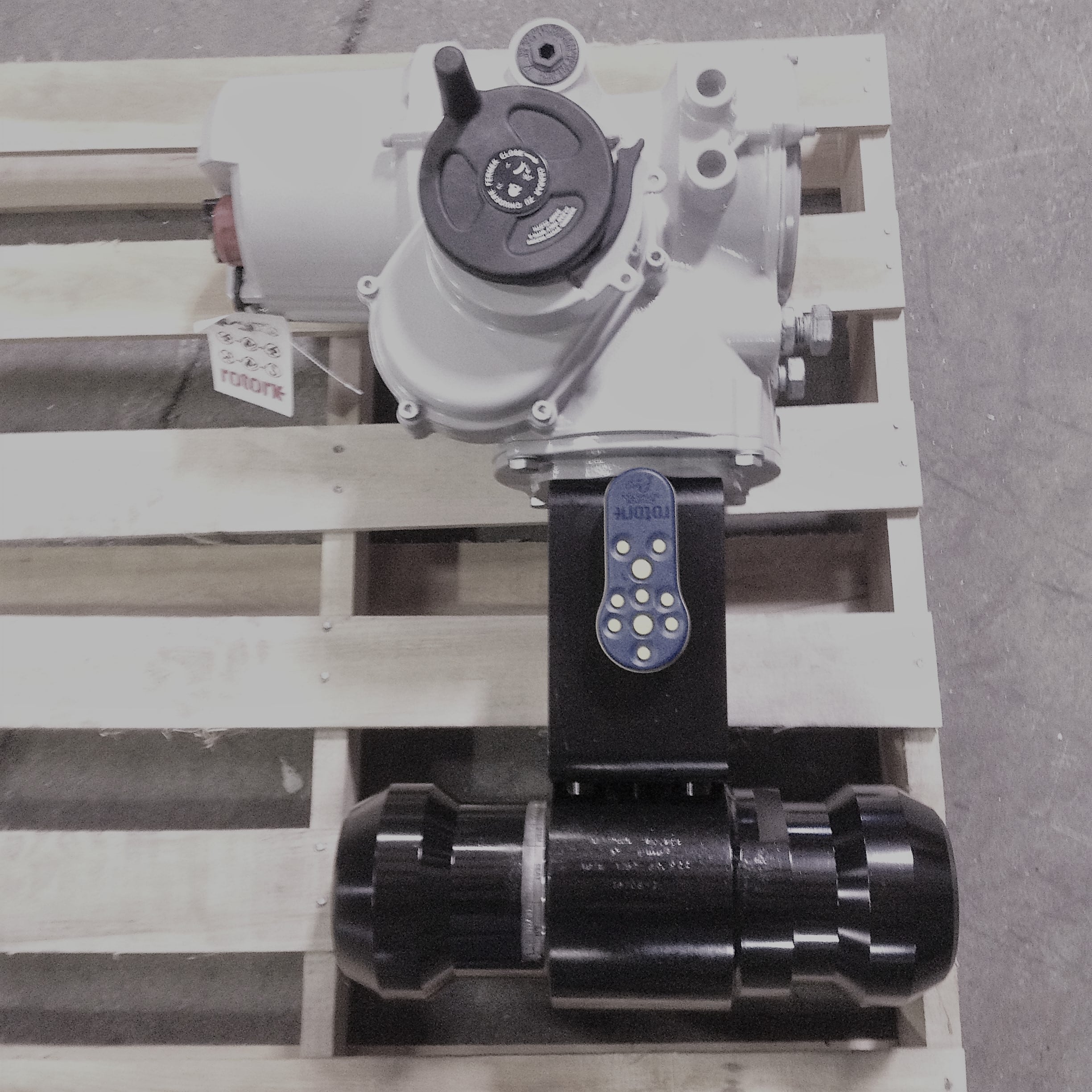

New Design For Testing Jet Fuel Pumps

When an Aerospace fuel pump test facility required valves for their testing facility Jarecki responded. The test required valves to handle jet fuel at -40 deg F to 300 deg F at 3000 psi while cycling often. Stem and body leakage were a major problem for previous valve designs. Jarecki solved the problem with a robust design which allowed for multiple resilient seals on the stem and body. The resilient seals were made specifically for jet fuel applications. The valves have been used in the testing of fuel pumps with no leakage for over year.

Phantom Port For High Cycle

A processing plant required a steam shut off valve to cycle every 6 seconds without fail. Jarecki installed their Phantom ported valve with Chrome Carbide coated trim. The Phantom Port reduces the wear on the valve seats by 75% improving the life of the trim. The valves have been utilized in this application for the past 5 years.

New Design For Fracking Valves

A pressure relief company required a ball valve to relieve pressure in the fracking system if the pressure exceeded 16,000 psi. The media was water with sand and at this pressure had destroyed the trim of previous valves that were used. Jarecki designed a ball valve to handle this harsh environment using boronized trim and a specially design ball which prevented erosion. Stoffel connections at the ball to stem connection allowed for the trim to handle the high torque involved.